Ceramic jewelry occupies a unique and important position in China's clothing culture system.In recent years, domestic and foreign jewelry industry practitioners have introduced cutting-edge technologies such as 3D printing to create high-precision ceramic jewelry products, with its excellent process texture and innovative design form, quickly won the wide favor of the market and consumers.

In the field of traditional jewelry design, most of the design schemes have been constrained by the backward manufacturing process system for a long time, which makes the creative thinking of designers gradually fall into invisible shackles.Because of the limitations of traditional processing technology, a large number of ingenious design ideas are forced to make compromises and concessions, which makes it difficult to achieve the perfect landing from drawings to finished products.The emergence of 3D printing technology has fundamentally broken through the technical barriers of traditional jewelry manufacturing, greatly reduced the threshold of mass production of complex structural products, unlocked unprecedented creative space for jewelry design, and endowed design with unlimited possibilities.

Finished ceramic window

Finished ceramic window

This time, Gu, a designer from the Jewelry College of China University of Geosciences, used the ceramic laser 3D printing technology of Intailai Laser to print a number of window styles in traditional Chinese architecture as the main body of the jewelry, and designed a set of windows as scenery, scenery as painting, cherry blossom growth as the time axis, combined with birds, fish and insects in different States.Such as magpie primrose, accompanied by early spring flowers, when flowers bloom, bees work hard to pollinate, falling flowers season, petals swing into the lake with the wind, beautiful fish in the lake.

Finished ceramic window

Finished ceramic window

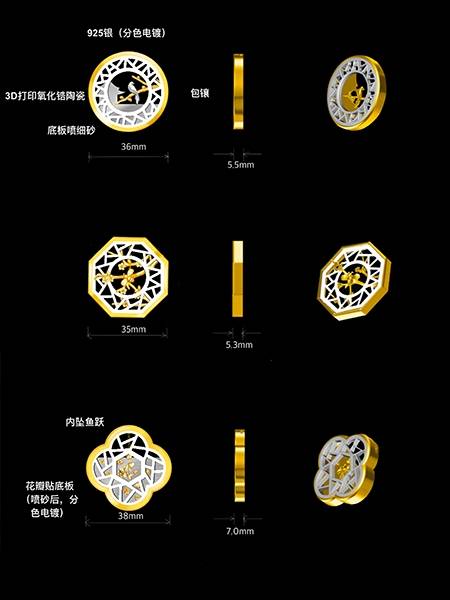

The whole series of works combines dynamic and static, hoping to make the audience feel the wonderful symbiosis of humanity and nature.The material used in the work is 3D printing zirconia ceramics, 925 silver.

Finished ceramic window

Ceramic window works series

The metal part is made of 925 silver, and the ceramic material is inlaid by the way of wrapping.The metal part is processed by color separation, electroplating, sandblasting and other processes to express different scenes and effects.

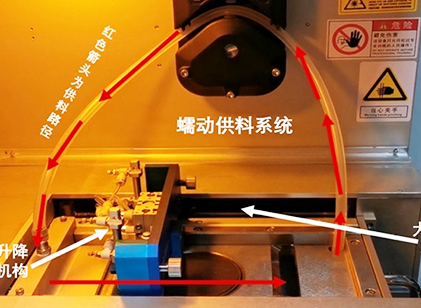

Ceramic laser 3D printing process

Print complete

In the traditional jewelry production process, the designer draws the design draft, gives the design draft to an experienced master to make the product silver plate, then presses the silver plate into a rubber mold, then takes the rubber mold to inject wax, weave wax (that is, the product wax plate), casts the wax plate into a gold blank, and then enters the factory to complete a series of processing links (such as holding the mold, inlaying stone, polishing, etc.), and finally produces the finished product.

Cleaning

With the application of ceramic laser 3D printing technology, the jewelry production process has entered the stage of full-link digital operation, and the core processes can be completed by computer software and professional forming equipment.

The specific process is as follows: First of all, the designer completes the digital design modeling through professional three-dimensional modeling software. Based on the generated three-dimensional model, it can not only realize the omni-directional visual preview of the finished product effect, but also accurately measure the key parameters such as the weight of gold materials and the specifications of gemstones, and complete the fine accounting of production costs.

Subsequently, technicians convert the design model data into processing instructions that can be recognized by the equipment, and the equipment directly uses the target material to print the jewelry gold holder according to the instructions.The gold support formed by this process has excellent precision and regular shape, which greatly reduces the man-hour input of subsequent polishing and mould holding processes, and ultimately achieves multiple benefits of simplifying the processing process, reducing the loss of raw materials, shortening the production cycle and improving the overall efficiency.

CeraBuilder series ceramic laser 3D printers have four core advantages: convenient operation, efficient molding, ultra-high precision and stable performance.Relying on the accumulation of industry-leading ceramic laser 3D printing technology, supplemented by years of deep technical experience of professional teams, it can maximize the landing of design schemes and realize the precise transformation of ceramic products from creative concepts to physical products.