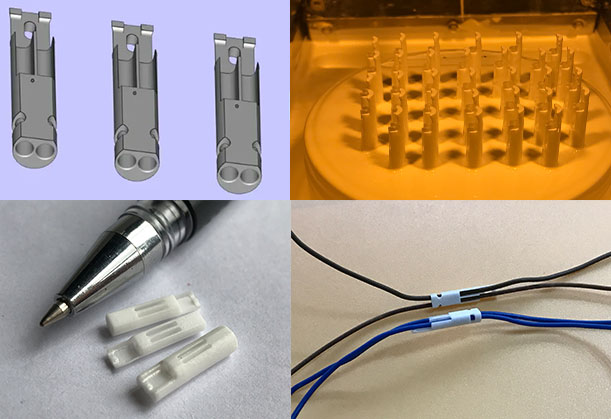

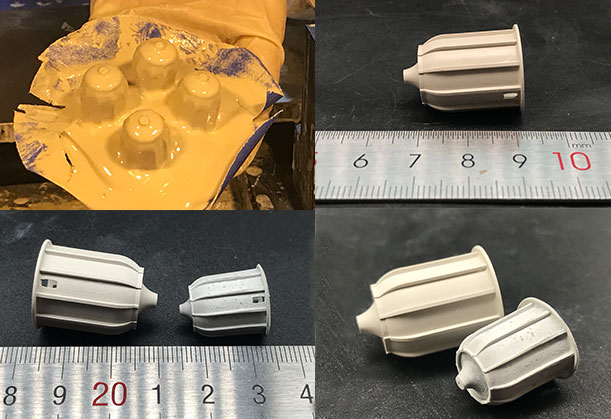

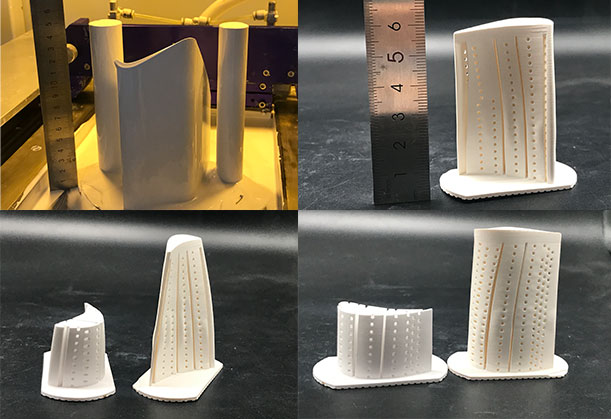

Aerospace sensor electronic bushing

Ceramic material is the best choice for aerospace sensor bushing material because of its excellent properties such as high compressive strength, high temperature resistance, corrosion resistance and poor conductor of electricity and heat. However, the aerospace sensor bushing is small in size, high in accuracy requirements and complex in shape, and the traditional process is difficult to manufacture.

ilaser uses SLA Plus technology, combines three-dimensional light curing technology with traditional ceramic casting process, controls the laser to focus on the surface of ceramic slurry, makes it solidify from point to line, from line to surface in order, goes round and round, and superimposes layer by layer to form a three-dimensional ceramic entity. The printed ceramic bushing has smooth and dense surface, no moisture absorption and stable insulation performance.The size error of the printed ceramic bushing is within ± 50 um, and the assembly accuracy is high and the installation is convenient.

CeraBuilder series ceramic laser 3D printer has the characteristics of simple operation, fast speed, high precision and stable performance, which is the best choice for making high-precision and complex structural parts.