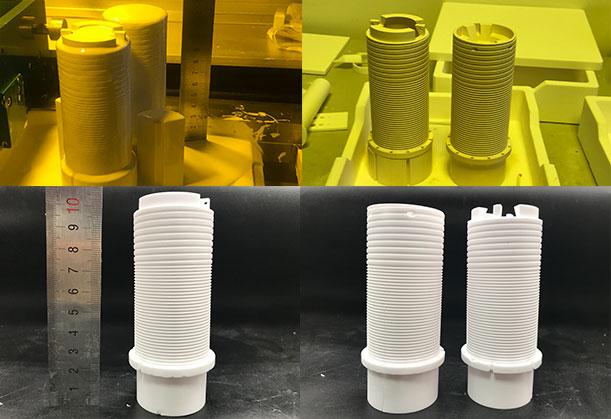

Vacuum chucks for the semiconductor industry

The core role of vacuum Chuck in the semiconductor industry is to achieve stable and damage-free wafer fixation through its unique vacuum technology principle, and to ensure the accuracy and stability of the semiconductor manufacturing process.

The application principle of the vacuum Chuck in the semiconductor industry is that the wafer is adsorbed on the surface of the Chuck by using the vacuum principle to avoid mechanical damage and pollution.The surface of the suction cup is designed with dense tiny holes, which are connected to the external vacuum pump system.After the vacuum pump is started, the air between the Chuck and the wafer is pumped out to form a vacuum area, and the wafer is firmly pressed on the surface of the Chuck under the external atmospheric pressure.

The vacuum Chuck can improve the production efficiency, reduce the dependence on manual operation, has high precision and stability, and ensures the precision and consistency of wafer processing.Adaptable to handle different sizes and types of wafer processing needs.