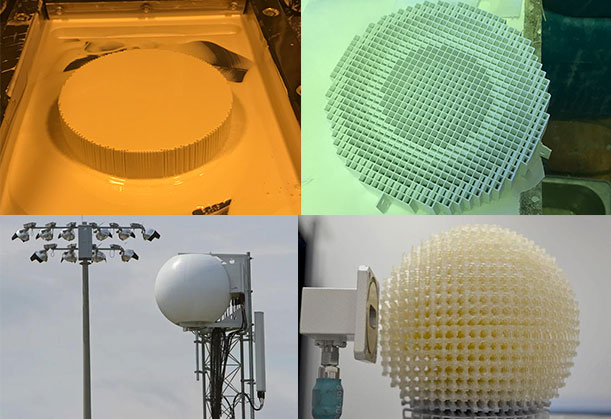

Application of ceramic 3D prin Longbo lens antenna in high frequency communication and RF 5G field

Traditional manufacturing techniques (dry pressing, injection molding, etc.) Have technical bottlenecks in the preparation, especially in the preparation of miniaturized complex ceramic devices, there are assembly gaps and dimensional errors, which seriously affect the high-frequency performance of the device.

As a new manufacturing process, 3D printing does not require molds, has high material utilization, high precision and stable performance, and is especially suitable for the development and design of device prototypes and the preparation of devices with complex structures.

By introducing the metamaterial structure, the gradient distribution of high dielectric constant ceramic medium is realized, and combined with the theory of transformation optics, a low-profile Longbo lens is obtained by using the SLA-Plus technology printing process of the Intralight laser.This technique can be extended to the development of low-cost ceramic microwave modules suitable for a wide range of operating frequencies.It proves that ceramic 3D printing technology has a good exploration and application prospect in the field of high frequency communication and RF 5G.