Product Center

Solutions

Information Center

About us

Contact us

Product Center

Solutions

Information Center

About us

Contact us

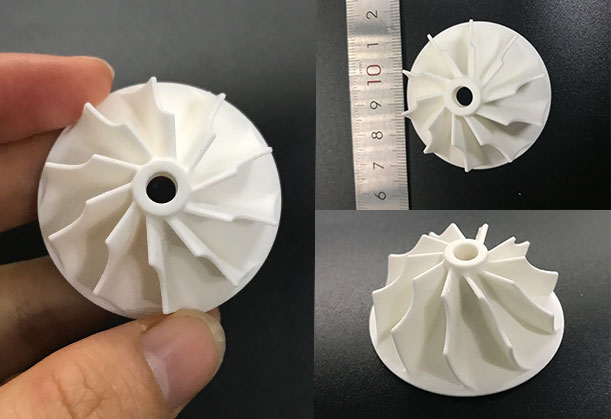

Construction machinery components are often required to have complex internal structures and geometric shapes, and traditional manufacturing methods are difficult to process these complex structures, while ceramic 3D printing technology can easily achieve the manufacture of complex structures without molds, thereby reducing manufacturing costs, therefore, ceramic 3D printing technology has a wide range of applications in the field of construction machinery.