Professor Huake Wu's project uses 3D printing technology of light-cured ceramics to realize 3D molding of albite

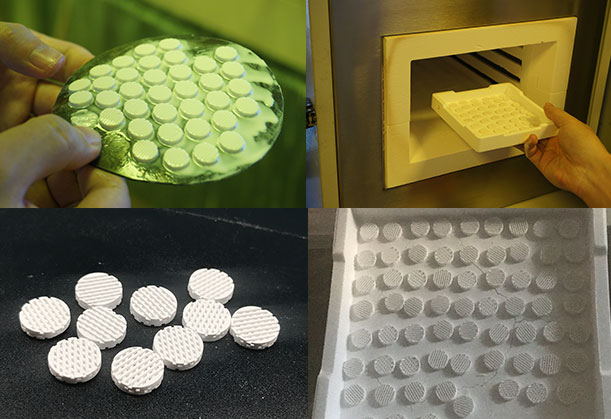

Yunnan is rich in mineral resources, with many kinds of minerals, large reserves and wide distribution. Albite is one of the local dominant minerals.However, at present, albite is mostly used as a flux as one of the raw materials in ceramic manufacturing, and its application in ceramic industry is limited.Photocuring technology has the advantages of fast forming speed, high precision and saving raw materials in the preparation of ceramic parts. Its basic principle is to print layer by layer according to the designed 3D model through ultraviolet laser beam, focus on the ceramic photosensitive resin mixed liquid in the working tank, and cure point by point, from point to line, from line to surface.After being solidified into a surface in the x-y direction, the three-dimensional printing ceramic material is completed by stacking layer by layer through the movement of the lifting platform in the z-axis direction.This process is very suitable for making products of different ceramic materials with complex structure and high precision requirements.

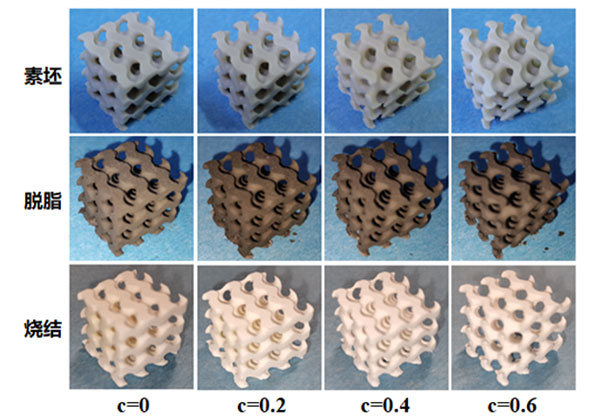

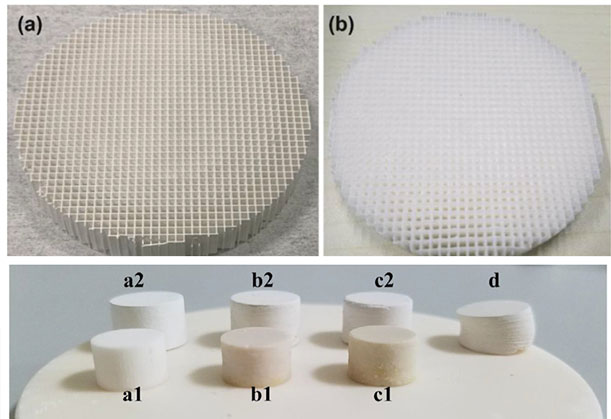

The research team led by Wu Jiamin, School of Materials Science and Engineering, Huazhong University of Science and Technology, used Yunnan albite as raw material to prepare high-performance Yunnan albite ceramics by using Intailai laser CeraBuilder 100 Pro ceramic 3D printer, and explored the manufacture of albite ceramics with complex structures.The effects of sintering temperature and Gyroid minimal surface structure on the properties of albite ceramics were studied.