Bone defect is a common clinical trauma and a major problem in clinical orthopaedics. In the past, bone transplantation was used to treat bone defect, and the development of transplantation materials has been a hot spot in the study of bone tissue engineering materials.Bone tissue is a natural composite of collagen and hydroxyapatite, consisting of 10% to 30% of a porous outer hard layer (cortical bone) and 30% to 90% of a porous inner layer (cancellous bone). The mechanical properties of cancellous bone vary greatly from cortical bone to cancellous bone, and are accompanied microscopically by complex geometries.At present, it is difficult to design an "ideal bone scaffold" for bone tissue, but the laser stereolithography forming technology (SLA-Puls) of Intralex laser can solve the difficulties of bone tissue scaffold manufacturing.

Recently, iLaser was entrusted by the Medical College of Huazhong University of Science and Technology to print a batch of biological scaffolds for bone transfer reagent research and testing. The company's technicians received this task and immediately arranged for printing production. This time, Intailai Laser used CeraBuilder100Pro, a self-developed ceramic 3D printer.The following is the whole process of printing production (Figure 1-Figure 7);

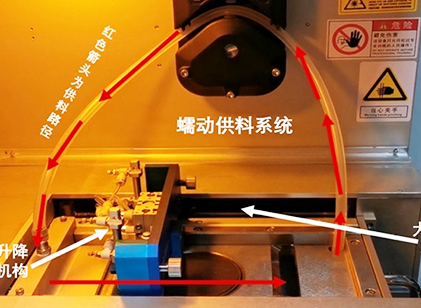

Ceramic 3D Printer CeraBuilder100Pro

Figure 2 In photocuring scan printing..

Figure 3 Print Complete

Figure 4 Cleaning

Fig. 5 Degreasing post-treatment process

Figure 6 Batch printing of finished products of biological stent

Figure 7 Detail display of printing finished product

Medical College of Huazhong University of Science and Technology uses Intrel laser 3D printing orthopaedic biological scaffold for bone metastasis research