Product Center

Solutions

Information Center

About us

Contact us

Product Center

Solutions

Information Center

About us

Contact us

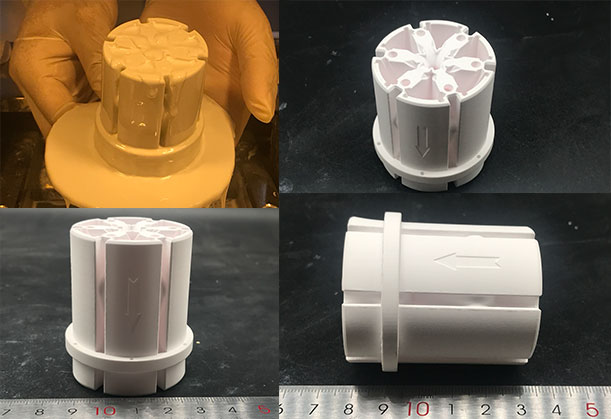

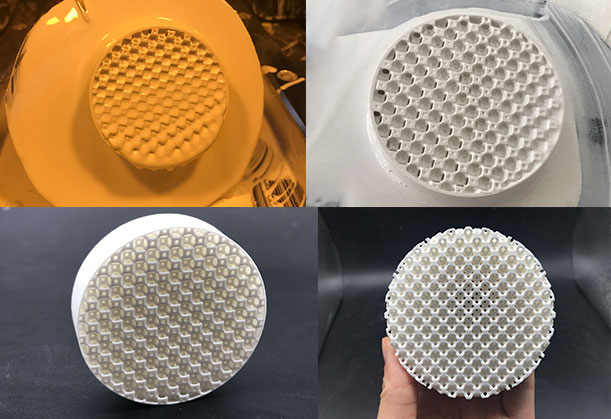

Ceramic 3D printing technology has a very broad application prospect in the fields of catalysts, separation membranes and gas sensors. Compared with the traditional ceramic forming process, 3D printing technology has intelligent, mold-free, precise and high-complexity manufacturing capabilities, and can complete manufacturing tasks that traditional processes can not complete.