Recently, the spinal surgery team of Shaoyang Central Hospital successfully treated a patient with complex, difficult and high-risk cervical spine fracture by using the world-class 3D printing technology, which is the first time in Shaoyang area to use personalized 3D printing interbody fusion cage for spinal stability reconstruction.It marks a new step in the field of precise treatment of complex cervical spine surgery in Shaoyang Central Hospital.

Qumou, 73 years old, was sent to Shaoyang Central Hospital for a fall from a height of 2 meters. After the patient was admitted to the hospital, the spinal surgery department immediately led a team of doctors to conduct a detailed inquiry and a comprehensive examination.The attending physician read the emergency CT and found that the patient had a complete anterior dislocation of the seventh cervical vertebra, combined with a severe fracture of the posterior appendages of the cervical vertebra, which was a rare complex fracture of the cervical vertebra in clinic. Physical examination found that although the main muscle strength of the patient's limbs decreased, it was still 3-4 levels. According to reason, patients with such fractures often had complete paralysis below the injury level, but the patient did not have total paralysis, which was a miracle of miracles.

After consultation, a personalized, systematic and standardized comprehensive treatment plan was finally formulated for the patients, using Professor Wang Wenjun's team's original intellectual property patent-3D printing titanium net (which was included in the 13th Five-Year Plan of National Key R & D and the major project of scientific and technological innovation of Hunan Science and Technology Department).

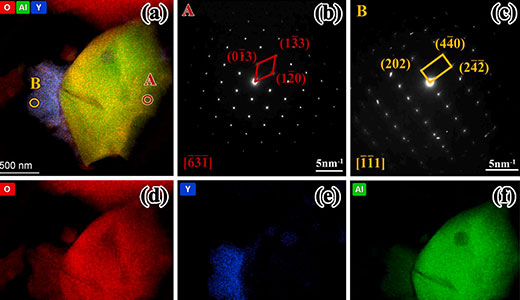

Preoperative CT data of cervical spine were collected for data reconstruction, and high-tech VR virtual technology was used to simulate the intraoperative situation, measure the relevant data, and determine the height and angle of cervical spine fracture reduction.The titanium mesh adopts a 3D bone trabecular truss structure, enlarges the contact surface of the end plate, prevents the titanium mesh from sinking after the operation, simultaneously takes into account the bone ingrowth of the upper and lower end plates, promotes the osseous fusion of the titanium mesh and the vertebral body, increases the fusion rate, and ensures the stability after the reduction of the cervical vertebra.

The operation was successfully completed in only 4 hours by posterior decompression and fixation, and then anterior decompression and 3D printing titanium mesh.At present, the patient's neurological function is gradually recovering, and the curative effect of the operation is satisfactory.

The success of this highly difficult operation marks a major breakthrough in the clinical application of 3D printing technology in spine surgery of Shaoyang Central Hospital, and also symbolizes that cervical spine surgery in Shaoyang area has begun to move towards personalization and precision, so that the masses in Shaoyang area can enjoy high-quality and precise medical services at "home gate" and benefit one side of the people.(Source: Antarctic Bear)